GENEL BİLGİLER

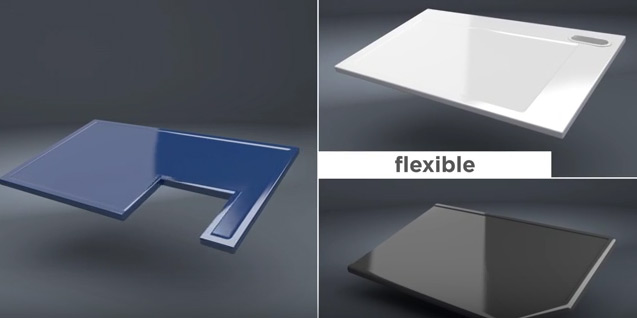

FRIDURIT® Modular Technical Industrial Ceramic Benchtops are DIN EN 14879-6 (chemical technical ceramics standards) compliant, 20 mm thick, one-piece, without raised edge and manufactured with 900 x 1800 mm maximum measurements.

They are resistant to all chemicals except HF, to corrosion by high concentrations such as solvents, aqua regia, hydrochloric acid, sulfuric acid, nitric acid, sodium hydroxide etc. and heat, long term chemical contact, color pigments and oils. They are scratch, fire and impact-resistant.

Perfect scratch resistance (Mohs Hardness Scale 7) prevents any marks of usage. They can be properly cleaned without damaging the work surface.

FRIDURIT® Modular laboratory benchtops can be used against walls or on island benches. It is an effective and economic choice that offers high performance under harsh conditions.

They can be manufactured in various sizes and colors.

TEKNİK BİLGİLER

| Test | Criteria | Unit | Result | Standard Deviation | |

| Density | EN 993-1 | g/cm³ | 2,37 | 0,00 | |

| Cold Pressure Resistance | EN 993-5 | MPa | 159 | 25 | |

| Bending Resistance | EN 993-6 | MPa | 41,3 | 0,6 | |

| Static Flexibility Value | EN 993-6 | GPa | 39 | 1,3 | |

| Heat Conductivity | EN 821-2 | W/mK | 1,57 | - | |

| Thermal Diffusion Coefficient |

DIN 51045-2 | 10 K | a(25-400) : 5,6 a(25-800) : 5,9 a(25-1200) :6,3 |

||

| Corrosion | DIN 52108 | cm³ / 50 cm² | 8,5 | 0,3 | |

| Hardness | DIN 101 | - | 6-7 | ||

| Stain Resistance | EN ISO 10545-14 | Category 5 | |||

| Crack Resistance | EN ISO 10545-11 | No cracking on the glaze surface on the ceramics. | |||

| Chemical Stability G: Glazed Plaque L: Interaction with Low Acid Concentrations H: Interaction with High Acid Concentrations A: Classification, No Effect |

EN ISO 10545-13 | NH4Cl | GA | ||

| NaClO | GA | ||||

| HCl 3 Vol- % | GLA | ||||

| HCl 18 Vol- % | GHA | ||||

| KOH 30 g/l | GLA | ||||

| KOH 100 g/l | GHA | ||||

| C6H8O7 | GLA | ||||

| C3H6O3 | GHA | ||||